Sleeving

Abrasion, in most cases, is caused by continuous rubbing against equipment components, other hose or objects in the operating environment. Cover erosion may also be caused by non-compatible fluids, such as toxic chemicals, acids, detergents and non-compatible hydraulic fluids. Exposed hose reinforcement is susceptible to rust and accelerated damage leading to failure.

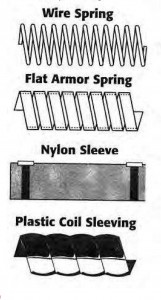

One solution is to bundle hose that flex in the same direction. Clamps, bent tube fittings, nylon ties, spring guards and sleeving can be used to keep hose away from abrasion sources and exposure to non-compatible fluids.

Remember to:

- Group and bundle similarly constructed and sized hoses together using clamps, nylon straps or nylon sleeving.

- Never bundle high pressure hose with low pressure hose. Under pressure they can work against each other.

- Never bundle rubber hose with thermoplastic or fluoropolymer hose. Under pressure they can also work against each other.

- Always consider mechanical movement when bundling. Allow sufficient slack without pulling on fitting or another hose. Bundles, like individual hoses, should bend in one plane only.

Another solution is the use of covers or sleeves.

© Copyright 2012 by the Association for Hose & Accessories Distribution, Inc.